Here's to actually doing projects and having fun doing them. The long anticipated construction of New Scooter (official name TBA, not to be confused with

Pneu Scooter) finally got its butt off the couch and went to the whiteboard for some calculations.

So lets say that I want to be able to climb a 10% grade on my scooter.

F = mg sin(theta)

F = 75 kg * 9.8 m/s^2 * .1

F = 73 N

This means that the force of gravity pulling me back down the hill is 73 N, and that I want 73 N pushing me up the hill. Lets say I want to climb the hill at 5 m/s.

P = linear force * linear velocity

P = 73 N * 5 m/s

P = 365 W

Torque = Force * radius, and I have a 6" diameter wheel.

T = F * r

T = 73 N * .076 m

T = 5.55 Nm

I'm planning on building a 33 volt LiFePO4 battery.

365 W = 33 v * 11.1 A

Now for my new favorite equation: Tea is for nibbler. I mean T = 4NIBLR

That is, Torque = 4 * # of wraps * Current * Strength of magnetic field * Length of stator * Radius of stator

For this calculation, we will estimate that the B field is about 1 T. This is an estimation, but it's really not far off of the actual value.

T = 4NIBLR

N = T/4IBLR

N = 5.55 Nm / 4 * 11.1 A * 1 T * .0254 m * .034 m

N = 144 wraps per phase

Now lets say the maximum current through quadruple 22 guage (four strands in parallel) wire is 40 amps peak. Replacing the 11.1 A in the equation with 40 A, we get N = 40 turns per phase.

If A = 11.1, N = 144 to get me up the hill.

If A = 40, N = 40 to get me up the hill.

Now for the torque constant, in Nm/A.

Kt = T/I = 4NBLR

For 11.1 A we get .5 Nm/A

For 40 A we get .14 Nm/A

1 Nm/A = 1 V/(radian/s)

33 v/(.5 v/rad/s) = 66 rad/s

and

33 v/ (.14 v/rad/s) = 236 rad/s

To calculate speed

66 rad/s * 1 rev/2 pi radians * 60 s/1 min * 60 min/1 hr * 2 pi (3 in)/1 rev * 1 ft/12 in * 1 mile/5280 ft = 11.2 mph

This is too slow. Well actually, it's a pretty safe speed, and at about twice the speed of me comfortably jogging somewhere, I'd be pretty happy going that speed. However, I'd like to go a little faster, so let's calculate my speed if I used the 40 A + N = 40 configuration. By multiplying by 236/66 we get 40 mph. As crazy as I am, I'd like to be able to build more vehicles after this project, so let's see if we can get something a bit slower.

At the advice of Shane, I wrapped the stator to see how many wraps I could reasonably fit onto one tooth.

AutoCAD predicts 95 wraps will fit if I wrap really tightly and ensure that each wire fits neatly in the valley of the two under it.

Realistically, I could fit 72 wraps of single strand 22 guage wire around one tooth, leaving room for some airflow and allowing for error in other teeth's wraps.

If we plug in 72 as N in our favorite equation, we get Kt = .248 Nm/A, which is right where it should be. According to

Shane, most electric kick scooters have a Kt of between .2 and .3 Nm/A. The higher side of this range will give a scooter more torque, but go slower, and a Kt on the lower side will go faster, but accelerate slower.

Kt = .248 Nm/A

5.55 Nm / .248 Nm/A = 22.4 A

33 v/ .248 v/rad/s) = 133 rad/s

Going the long way again:

130 rad/s * 1 rev/2 pi radians * 60 s/1 min * 60 min/1 hr * 2 pi (3 in)/1 rev * 1 ft/12 in * 1 mile/5280 ft = about 22 mph

This is about right. Fast enough to actually be used as transportation somewhere, and torquey enough to get me up to speed quickly and scare other people who want to try my little toy.

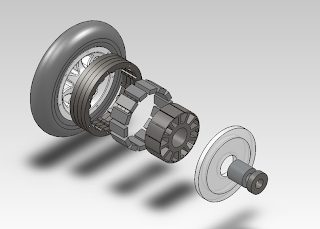

Hopefully I'll wrap the stator sometime in the next two weeks, and then get to the construction of the body, battery, and turning of the rotor can and spacers.

Let the scooter building season begin...